the process

The process starts by determining if your tank is clean or if it contains contaminents like water, micro-organisms or bacteria. This is accomplished by taking a fuel sample and visually analyzing the sample. If desired, the sample can be taken from different levels inside the tank to determine the amount of contaminents.

If the tank does show contamination a cleaning of the tank should be scheduled. The cleaning process utilizes equipment that will pump the contents from the bottom of the tank. The equipment will pull the pumped fuel through either a 5 micron or 1 micron filter. The filter traps any sediments and allows only liquid to pass.

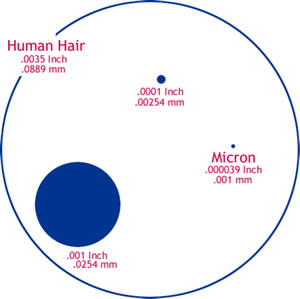

As illustrated by the picture to the right, the diameter of human hair is depicted by the outside blue circle. The smallest blue dot to the right side of the picture is 1 micron. The human hair circle can contain 3,461 of the 1 micron blue circles.

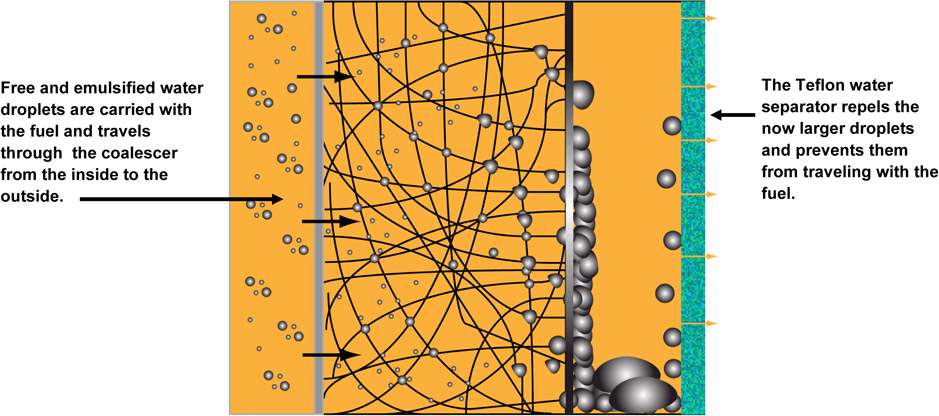

The fuel and water mixture coming from the tank are then passed through a coalesser. The coalesser contains a micro fiber multi-stage process that forces the fuel through the coalesser separating the water from the fuel. The water drops adhere to the fibers but the fuel does not. The water then drops down and the fuel is allowed to pass. The water is then sent through a discharge valve to a waste storage tank. The clean fuel is returned to the tank.

We monitor 2 important indicators on the equipment. A sight glass on the equipment tells us what has been collected and if any water is still being filtered out of the tank and a vacuum gauge that will tell us if the 1 or 5 micron filter is becoming clogged with particulates. If that is the case, the filter is changed and the system continues cycling until no high vacuum is sensed.